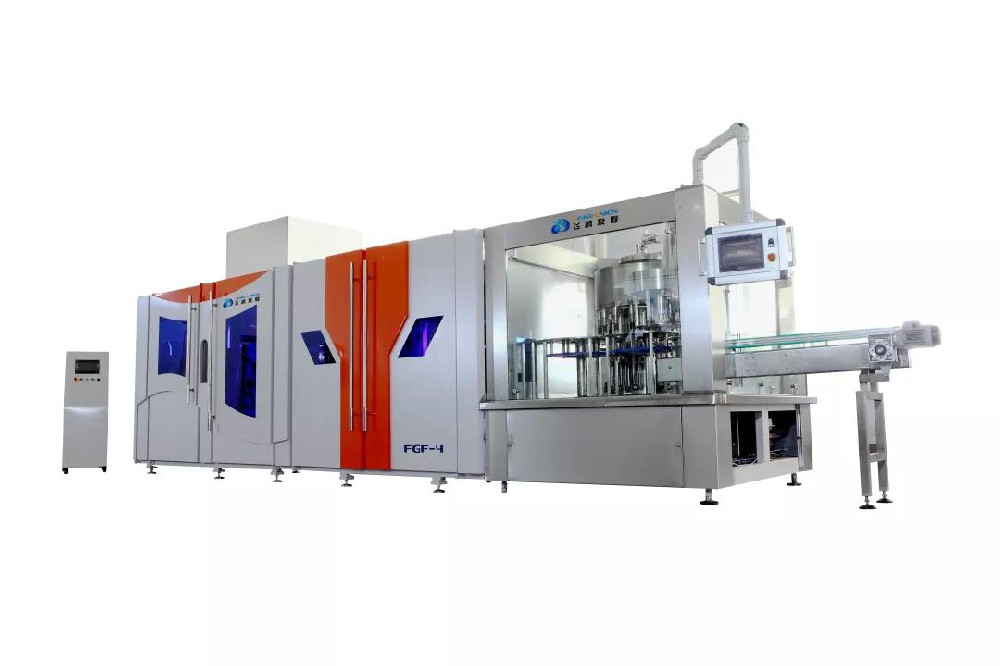

Blowing, filling and spinning machine refers to the complete package of blowing, filling and capping on a single device, and a single device to complete the innovative packaging technology from preform to bottled liquid products. The traditional blow-fill-spin machine adopts one-to-one conveying method. Once the filling machine is shut down, the preforms that have entered the blowing system can not be re-entered into the filling system after being blown into bottles, so they are discarded and filled. Every time the machine stops, hundreds of bottles will be wasted. FAYGO UNION Co., Ltd. has a limited company, and developed a linear blow-fill-spin machine to solve this problem ingeniously.

Advantages and disadvantages of FAYGO UNION linear blow-fill-spin machine:

Advantage:

1. Save installation space

2. Save equipment investment

3. Save water consumption

4. Save power consumption

5. Save operators

6. Save maintenance costs

7. Less waste of finished bottles (Once the filling machine is shut down, the preforms that have entered the bottle blowing system can be re-entered into the filling system after being blown into bottles, thereby reducing waste).

8. Can it meet the needs of small and medium-sized products of small and medium-sized enterprises

Disadvantages:

The small output (6500 --- 26000 bottles / hour) cannot meet the capacity needs of large enterprises

Model: FGF4

Bottle specifications: the maximum volume of the bottle (mL) 2000

Maximum height of bottle (mm) 328

The maximum diameter of the bottle (mm) 105

Maximum diagonal length of square bottle (mm) 115

Preform specification: inner diameter of bottle mouth (mm) 20--25

The maximum length of preform (mm) 150