PET sheet production equipment produced by our company has a compact structure and stable performance. It can produce single-layer and multi-layer PET sheet products with thickness 0.15-1.5mm, maximum width 1500mm and maximum output 700KG / H.

The PET sheet produced by this equipment can be processed into various packaging products by thermoforming. It has good gas barrier properties, does not contain other additives, is pure and hygienic, has good toughness and extensibility, and excellent recycling characteristics. It can be widely used in electrical appliances, toys, food, medicine and other packaging and the printing industry. The extruder adopts special screw structure and optimized design of the barrel. The machine has uniform plasticization, stable extrusion, high output and long life. 100% recycled materials can be used. Among them, the traditional crystal drying equipment plus single screw extruder is suitable for high-quality sheet processing requirements. Twin-screw exhaust extruder can greatly reduce equipment energy consumption.

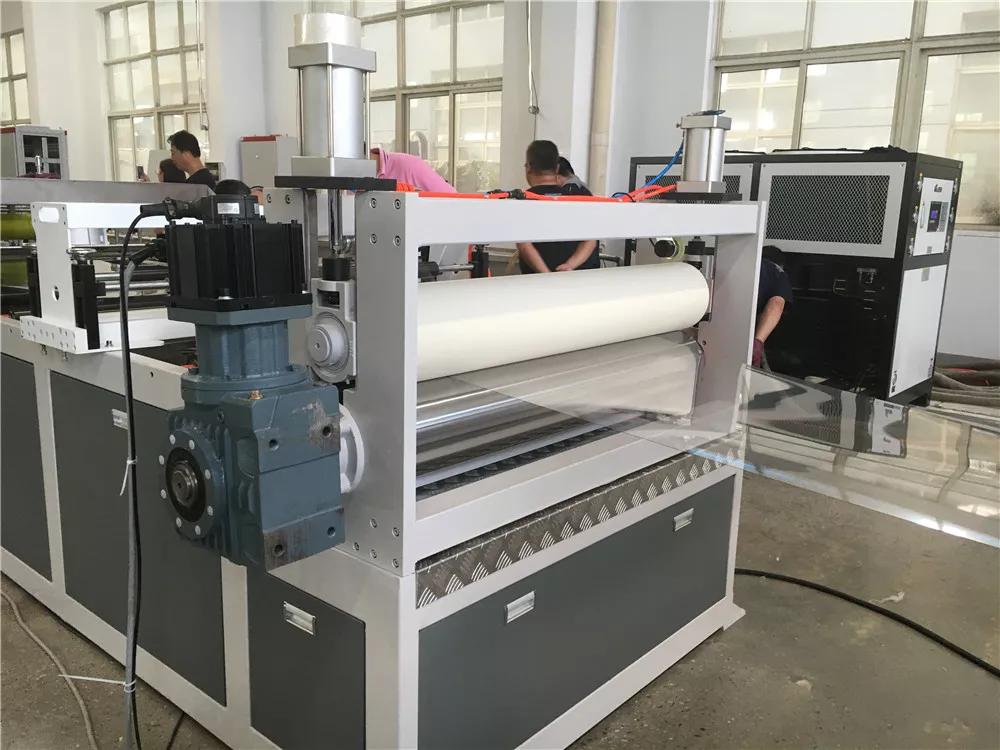

The three-roller calender adopts precise stereotyped calendering device. It has three types of vertical, oblique vertical and horizontal structures, which are suitable for different operation requirements. Through its good adjustment function, the sheet is shaped well.

PET film material introduction:

Polyester sheet (APET film) has good finish and transparency, and good gas preservation. Compared with other plastic sheets, it has the following advantages:

(1) The product has a beautiful and transparent appearance;

(2) The gas has strong preservation;

(3) Sanitation does not contain any stabilizers and plasticizers, so no other harmful elements are discharged;

(4) Good quality is toughness and extension;

(5) After burning, no toxin gas is discharged, the waste is easy to handle, and meets the requirements of environmental protection.

PET sheet has the following characteristics:

(1) High transparency and good gloss.

(2) Strong self-adhesion and excellent barrier resistance.

(3) No whitish stress, folding resistance

(4) Good chemical stability, not easy to corrode

(5) Low temperature embrittlement resistance

Common specifications: 0.2-1.5mm * 915 * 1220mm

Coil specifications: 0.012-0.5mm * 510-1800mm width

1.Roll sheets and film sheets of various widths and thicknesses; color: transparent, milky white translucent, milky white film.

2.PET flat sheets of various specifications;

3.Various special purpose PET sheets, various color sheets (produced according to customer requirements)

4.Printed sheets of various specifications (corona treatment, thickness: 0.125mm-3.0mm)

Milky white coiled material: 0.12 / 0.188 / 0.2 / 0.25 / 0.35 / 0.38mm width 1000-1200mm

Product features: Thermoplastic environmental protection plastic products, odorless and tasteless after burning, do not produce toxic gases. High transparency, no water ripples on the surface, no crystal points, no biphasic whitening: grease resistance and chemical resistance: toughness and rigidity, good impact resistance strength (low temperature impact strength is also good, about 20% higher than PVC). Used for blister, folding box, packaging, printing, card making, etc.

Play live production video.