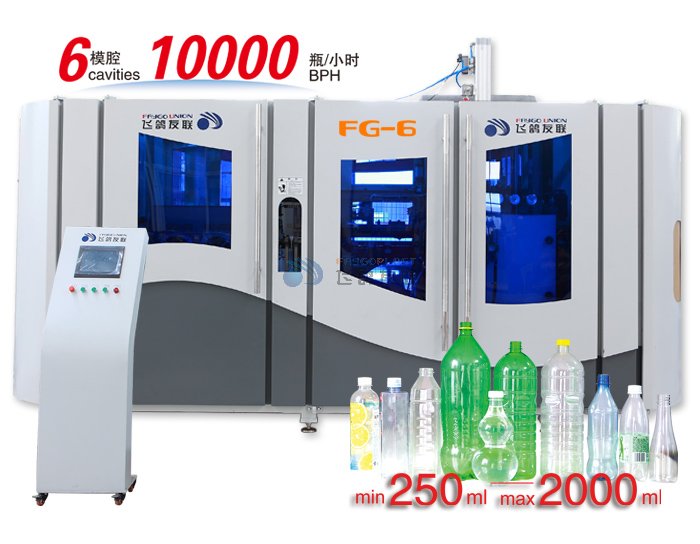

FG6 Pet bottle blowing machine

1.FG 6 PET Bottle Blowing Machine Description:

FG6 PET bottle blowing machine fills the gaps in the domestic high-speed linear blowing machine. Currently, domestic single-mold speed of linear blowing machine still stay 1200-1500BPH, while international max single mold speed has reached 1800BPH. High-speed linear blowing machines rely on imports. In view of this situation, Faygo Union Machinery developed China first high speed linear blowing machine: FG6 The single mold speed can reach 1800 BPH.

2.FG Series PET Bottle Blowing Machine Advantages:

2.1 Increasing output(doubled) Rotary perform uploading, soft and continuous, preform continuous running, instead of step by step, movement more soft.

2.2 Reduce Bad Bottle Rate. Only equipped with two heating box, each heating head distance minimized to 38.1mm, which can reduce 30% electric than the traditional one, around 130000kwh electric power, so one year based on 8 hours per day, can save 20000USD money for you only on heating power;

2.3 With Switherland brand electric ammeter to help you check every single bottle cost.

2.4 The unique cam linking system to integrate mold-opening, mold-locking and bottom mold elevating in one movement, it is controlled by servo driving system, which greatly shorten the blowing cycle and increase the speed.

2.5 Less dead zone=less air compressor, our blowing machine no need LP air compressor& air cylinder to control the movement, as bottom mold elevate, mold close and mold lock is integrated in one cam, the cam is driven by servo motor.

Same speed blow machine we save 1-2m3/min=save 20-30kw=save 8000-10000USD per year for you.

2.6 Reduce bad bottle rate, other machine below 0.3%, ours below 0.1%. As our molds adopt modularized design to make it convenient changing, if you have more than 2 sets bottle sizes, mold changing only 25 minutes. Also with Magnalium6061 material photos are below:

FG4-6 Optional items:

1) Exploded bottles ejection unit

During the blowing process, if the bottle burst, bad bottles can be automatically removed. This prevents the bad bottles from entering the filling machine.

2) HP air recovery system

After the bottle blowing, high-pressure air can be recycled and used again for the pre-blowing and machine physical movement.

3) Oven and preform temperature detection system

Detection system detects temperature of oven and the temperature of performs. When the preform temperature does not reach the set blowing temperature, blowing workstation will alarm, not blown.

Technical Parameter:

Type | FG4 | FG6 | FG8 | Mark |

Specifications of bottle | Mould number(piece) | 4 | 6 | 8 |

|

maxi volume (mL) | 2000 | 2000 | 2000 |

|

maxi height (mm) | 328 | 328 | 328 |

|

maxi diameter (mm) | 105 | 105 | 105 |

|

Square bottle for max diagonal length (mm) | 115 | 115 | 115 |

|

preform Specifications | Suitable inner bottle neck (mm) | 20-25 | 20-25 | 20-25 |

|

preform max length (mm) | 150 | 150 | 150 |

|

Capacity (bottles / hour) at 17 g 500mL | 7200 | 9600 | 12000 |

|

Electricity | Install power (kw) | 51 | 74 | 97 |

|

Heating oven total power (kw) | 46 | 69 | 92 |

|

Heating oven actual power consumption (kw) | 26 | 40 | 50 |

|

Voltage / frequency (V / Hz) | 380v,50hz | 380v,50hz | 380v,50hz |

|

Allowed voltage fluctuation | ±10% | ±10% | ±10% |

|

HP Air | Pressure(bar) | 30 | 30 | 30 |

|

Capacity(m³/min) | 4 | 5.5 | 7 |

|

Cooling Water | Mold water | pressure(bar) | 4-6 | 4-6 | 4-6 | Water chiller 5HP |

Suitable temperature range (℃) | 6-13 | 6-13 | 6-13 |

Flow (L / min) | 45 | 45 | 45 |

Oven water | pressure(bar) | 4-6 | 4-6 | 4-6 | Water chiller 5HP |

Suitable temperature range (℃) | 6-13 | 6-13 | 6-13 |

Flow (L / min) | 22 | 22 | 22 |

Machine Specification | host machine dimension (m) length × width × height | 3.3*1*2.3 | 4.3*1*2.3 | 4.8*1*2.3 |

|

Weight (Kg) | 3200 | 4000 | 4500 |

|

Note: the parameter above is based on the 17 grams of 500mL PET bottles. If the bottle conditions change, the corresponding parameter will change also. With the development and innovation of technology, the data above may be changed or improved, so it is for reference only. For precise and detailed data, please consult our technical department.

engineer in customer factory

High Quality Automatic PLastic PET Bottle Blowing Making Machine Price With CE Approved

Our Company