Automatic Water Washing Filling Capping Machine CGF

1. Filling Product: Mineral water, pure water, still water etc.

2. Suitable bottle and cap: PET bottle with size 200-2500ml and plastic screw cap

3. Capacity: 3000-36000BPH(500ml)

4. Normal pressure filling technology for the water refilling equipment.

This water filling machine adopts bottle-neck block technology, not only avoiding second pollution to the bottle-neck, but also realizing filling different specs of bottles in one equipment, which greatly improved commonality of this equipment. Production capacity is 3000 bottles to 36000 bottles per hour. Main-frame machine adopts frequency controlling electric motor, which is much corwenient to adjust speed in scope of production capacity

The Technical Parameter :

| Model | Washing heads | Filling heads | Capping heads | Production capacity (b/h) | Power of main motor (kw) |

| CGF14-12-5 | 14 | 12 | 5 | 5000 | 2.0 |

| CGF18-18-6 | 18 | 18 | 6 | 8000 | 3.5 |

| CGF24-24-8 | 24 | 24 | 8 | 12000 | 4.5 |

| CGF32-32-10 | 32 | 32 | 10 | 15000 | 5.5 |

| CGF40-40-10 | 40 | 40 | 10 | 18000 | 5.5 |

| CGF50-50-12 | 50 | 50 | 12 | 24000 | 7.5 |

| CGF60-60-15 | 60 | 60 | 15 | 28000 | 11 |

| CGF72-72-16 | 72 | 72 | 16 | 32000 | 15 |

Main Features of this water filling machine:

1. Using Main Features of this water filling machine:

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Machine Description:

High and Precise Filling Valve

Cap Sensor

Bottle Sensor

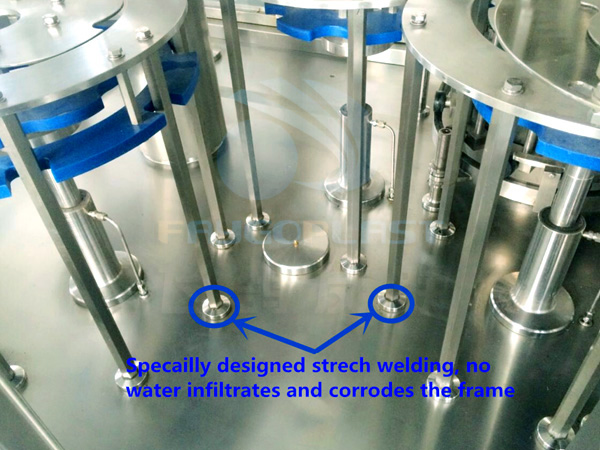

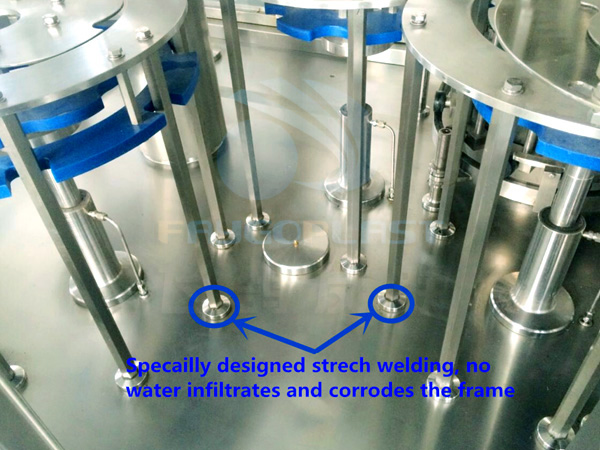

Platform-Smooth and Anti-leaking

Bottle Conveyor

Packaging a Better Life with You